GERASIMOS (Gerry) D. DANILATOS was born on the Greek island of Kefalonia in December of 1945. He moved with his family to the city of Patra after the island was devastated by a strong 7.3 Richter scale earthquake. There, he finished his primary and secondary schooling. He entered the National and Kapodistrian University of Athens in 1965 but was conscripted to the army and forced to interrupt his studies for two years between 1966-1968. He then resumed his studies and received his Physics Degree with distinction in 1972. He worked as a casual teacher in a private school for about a year.

From 1967 to 1974, Greece was thrown into turmoil by the Greek junta threatening civil & human rights. When Danilatos was approved for a position in the School of Electronics at Patra University by the academic board, the Ministry of Education under the military junta blocked his appointment on political grounds.

Forced to abandon his career in his homeland, Danilatos migrated to Australia in December of 1972 to pursue an academic career where he obtained his Ph.D. thesis from the University of New South Wales (UNSW) in January of 1978. His thesis entitled "Dynamic Mechanical Properties of Keratin Fibres" involved research into the viscoelastic/molecular properties of keratin fibres, which was part of a major research program in the School of Textile Physics. Several publications from his thesis have appeared in official journals of the field that continue to be referenced to date. He established his life in Sydney, Australia, married in 1979 and has two children.

Danilatos became a research scientist by accepting a non-tenured position with the scanning electron microsope (SEM) available at the School of Textile Physics in January of 1978. He was initially funded by an Australian government research grant, but soon he obtained his own (external) research grant that permitted him to continue his work independently.

Following an initial investigation into prior attempts to introduce gas in the vacuum of electron microscopes, he was supported by the Wool Research Trust Fund at the recommendation of the Australian Wool Corporation (AWC) to apply his work to wool fibre research. That also allowed him to further develop his microscopical techniques at the same time. Work on this project continued until 1986. Numerous publications have resulted in various journals in microscopy with a high referencing continued to date.

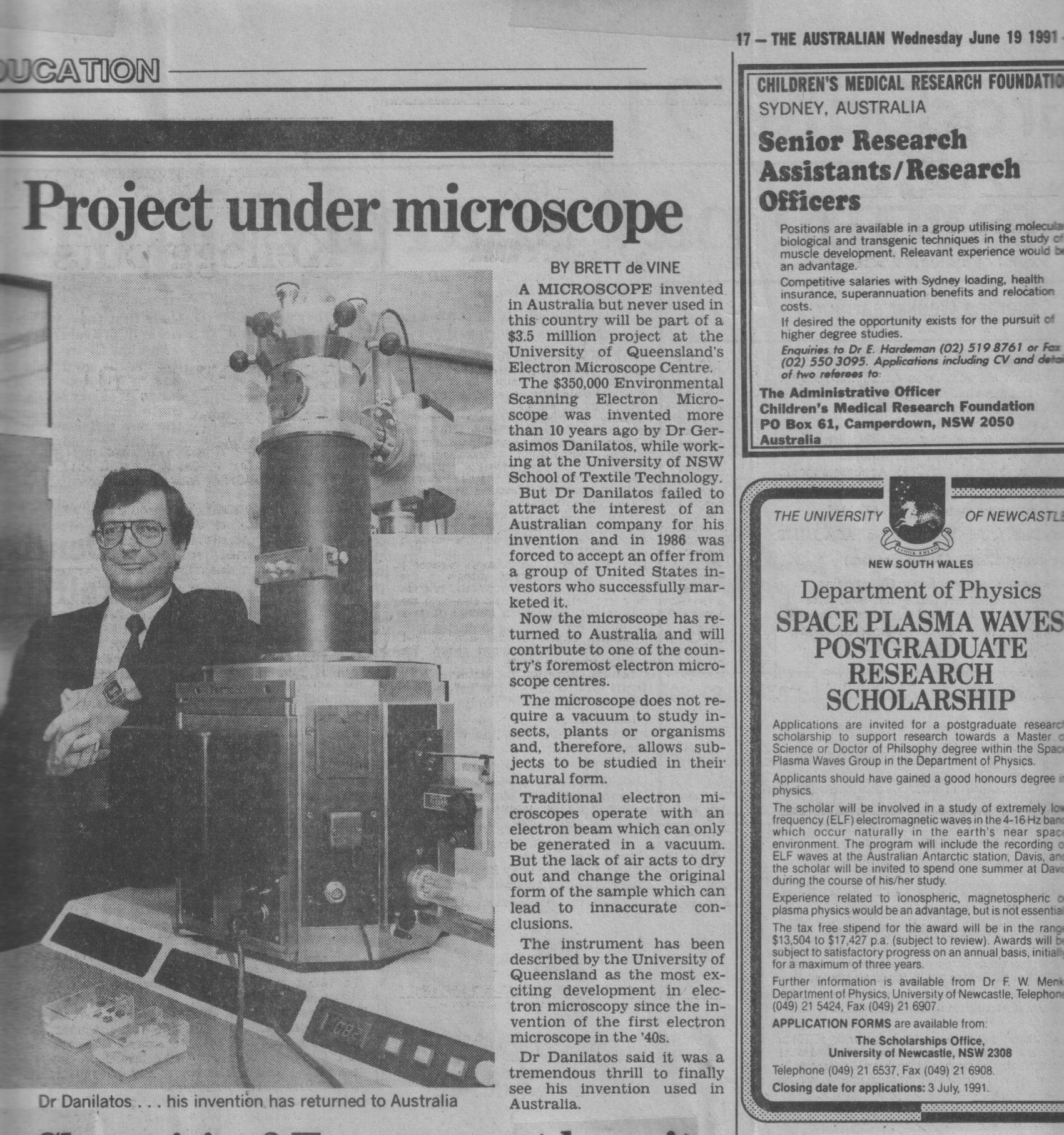

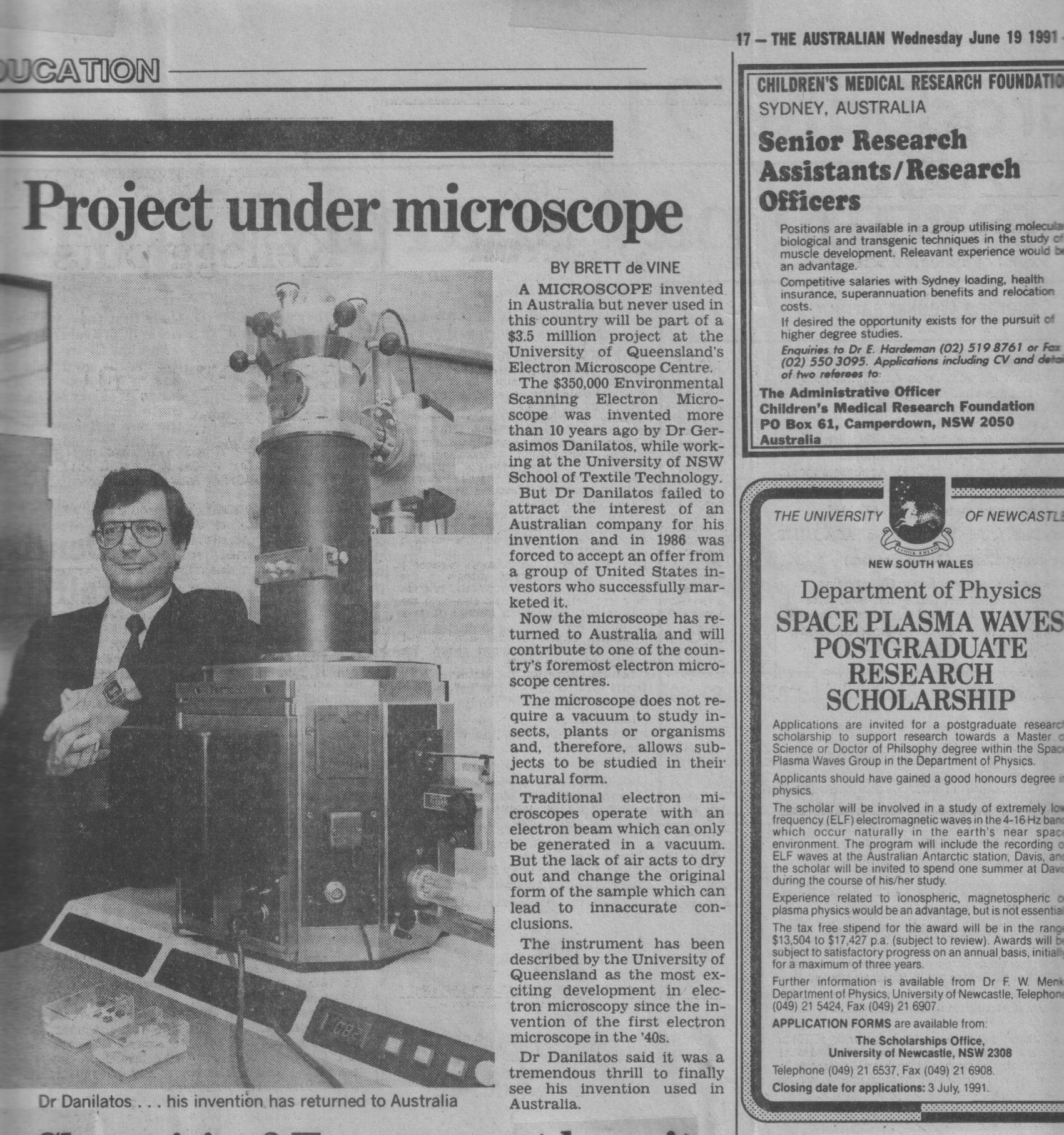

He is best known for his pioneering work on the environmental scanning electron microscope (ESEM) developed during his wool project research and afterwards until the present times. The establishment of ESEM did not occur overnight and without trouble. Despite the successful outcomes of his work and not quite appreciated and supported by his peers in that early phase, the UNSW withdrew the availability of its premises for other projects. However, the AWC undertook to fund the relocation of the entire ESEM research laboratory equipment with Danilatos elsewhere. With the financial support of AWC, work continued on the same project at the Textile Physics Division of the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Sydney from 1983 to 1986. Three years of independent and fruitful work yielded a critical impetus to the development of his technology of ESEM with simultaneous application to wool fibre research. This is evidenced by the continuing publications and presentations to international conferences. Despite all these successes, he had to apply for renewal of his stay at the CSIRO premises annually; he was never offered a tenured position, unless he agreed to give up his ESEM project and integrate with other ongoing projects at other Divisions of the CSIRO: Despite the high level of development reached by ESEM, it appeared to fall outside the programs of work at CSIRO. Clearly, the nature of his work was not properly appreciated even if he could secure continuing external funding by the AWC. He was formally advised to terminate his activity by mid-1986.

As Danilatos’ time at CSIRO came to an end, ElectroScan Corporation in the US was formed for the purpose of manufacturing a gaseous scanning electron microscope; Danilatos was invited to the headquarters of the company at Boston where a proposal to guide the R&D program of that company was accepted. He became the Chief Scientific Advisor to ElectroScan, operating from Sydney with frequent visits to and communications with the company. The operations in Sydney involved the establishment of a private ESEM Research Laboratory supplied with the entire CSIRO laboratory equipment and funded by ElectroScan. The ESEM prototype and ancillary equipment were promptly supplied and transferred by CSIRO without charge. ElectroScan should be credited for rescuing Danilatos' technology via his publications that professed exactly what the manufacturer needed. He is a notable scientist in the field of electron microscopy [1, 2, 3, 4, 5, 6, 7, 8].

Thus the ESEM Research Laboratory was founded, a private research and development unit of electron microscopy that has played a key role in the development of ESEM ever since. Work was secured to continue on ESEM with Danilatos as Director in Sydney and Advisor of the company in the US until 1993. He was thus able to completely independently continue his project of choice whilst ElectroScan undertook to manufacture the first commercial ESEM under licence and assignment of various patents. It has been from this laboratory that some of the most voluminous and best works on ESEM have originated, some of which have become the standard reference points (3, 4) for most ensuing later works involving ESEM. He has continued to work and produce results until the present day while he endeavours to help manufacturers to produce new generations of commercial ESEMs with new capabilities and attuned to optimum operation.

After 1993, ElectroScan Corporation being a venture capital company was acquired by Philips for several years, which was then succeeded by FEI Company, which was succeeded by ThermoFisher company. From 2000, Danilatos further worked for a few years to help LEO (now ZEISS) enter the ESEM market with a new commercial ESEM that allows the use of secondary electron detection via scintillation cascade amplification with extended specimen chamber pressure. NASA has also used the Danilatos services in the design of a mini-ESEM [9] for a possible future mission to study specimens on the surface of Mars (2015-2017). The ESEM and its variants have thus continued to be manufactured under various brand names. He is currently an an Affiliated Scientist at the Foundation Reasearch and Technology Hellas (FORTH/ICE-HT).

Danilatos held the position of Senior Research Scientist at CSIRO (1983-1986). Prior to that, he was Project Scientist (1980-1983) and Professional Officer (1978-1979) at the UNSW. He has served as member of the Scientific Advisory Board of the journal Scanning (1983-1988) and has been a member of the Royal Microscopical Society (1979-1994), a member of the Microscopical Society of America (1986-1993) and a member of the Australian Society of Electron Microscopy (1979-2008).

He is the senior author on over seventy publications in international refereed journals including three major chapters on ESEM and has obtained over ten patents on various aspects of ESEM technology.

He received the Ernst Abbe Memorial Award by the New York Microscopical Society in 2003.

It was the tenacity and absolute conviction by Dr. Danilatos in his technology that kept him going for a long time despite relatively meagre support and numerous obstacles he had to face during the critical years of his work. He indeed achieved an extraordinary result in an unconventional way. He now plans to bring his work to its logical conclusion by further research and new publications on ESEM to be used by the scientific and manufacturing communities. He has consulted with TESCAN recently to help them enter the ESEM market. His works constitute an introduction and the basis in the understanding and use of ESEM. Danilatos is honoured to have been instrumental in developing the ESEM instrument to a point where the rest of the scientific and manufacturing world can further develop, expand, apply, use, benefit and enjoy.

DYNAMIC MECHANICAL PROPERTIES OF KERATIN FIBRES

The complex modulus of single keratin fibres has been studied at various extensions or times as well as at different relative humidities, temperatures and frequencies. Two parameters of the complex modulus were measured, namely, the dynamic modulus and the loss angle.

To carry out measurements for the above studies, a dynamic mechanical tester was designed and constructed. By using a piezo-electric element, the apparatus allows for measurements to be taken in the frequency range 6 Hz to 1500 Hz, while with an environment conditioning chamber the full range of relative humidities and the range of -100 to +50 0C for temperatures can be covered. Fine fibre samples can be extended in the apparatus and tested at each extension. Considerable precautions were taken in the apparatus to reduce noise because of the small values of the signals detected.

By using the above equipment, it was found that the modulus of wool fibres decreases with strain up to intermediate extensions of about 20% and then increases with higher extensions. The loss angle variation with extension is inverse to the modulus changes. The complex modulus was also measured while fibres were extension cycled or relaxed at fixed strains. More measurements were taken under other specific conditions of strain. All of these results, it was shown, could be explained by the application of a two-phase structure model of keratin: one crystalline phase C being relatively impenetrable to water and possessing elastic properties at all extensions, and the other phase M being water penetrable and acting mechanically as a viscoelastic solid.

Measurements on fibres were carried out during abrupt relative humidity changes at a constant frequency and temperature. For an abrupt relative humidity increase, it was found that the loss angle vs. time exhibits an overshoot at the time when the absorption is nearly completed, while the modulus curve is changing markedly at the same time. This result was compatible with the suggestion that the structural mobility of the keratin fibre reaches a maximum at the time when absorption is almost complete.

The complex modulus of wet keratin fibres was measured in the frequency range of 6-1500 Hz, at different temperatures between 0.2-45 0C. Some measurements were taken at different relative humidities. These results together with results of other workers indicated the presence of a characteristic transition process in keratin dependent strongly on the water content. This process was attributed to the main chain motion in the M phase.

Detailed description of these works is given in the literature below.

Primary and secondary sources about Danilatos